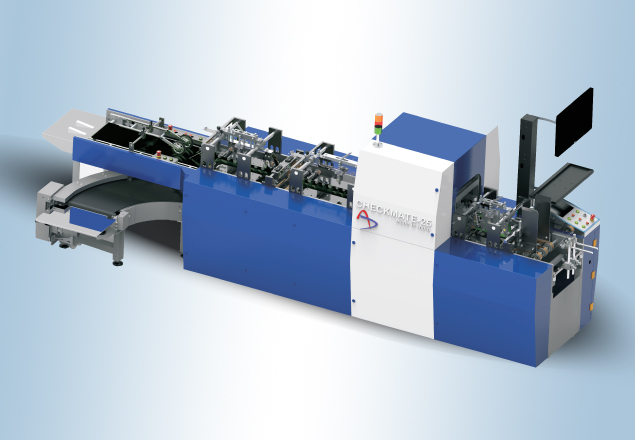

Autoprint is committed to bring modern cutting-edge technology to its customers. A result of this commitment is Autoprint CHECKMATE 25 a revolution in imaging technology for defect free print products to the end customer with 100% accuracy.

Autoprint CHECKMATE 25 can inspect print defects and foil errors. The machine segregates the good and defective sheets neatly into different stacks which can be further analysed to correct the previous process. Autoprint CHECKMATE 25 eliminates expensive manual labour while enhancing the checking speed and process.

Features at a Glance

Bottom feeding system with vibrator for trouble free feeding

Air jets are provided for removing dust / fluff from cartons.

Ultrasonic double sheet detector to detect double sheets automatically and take them to reject bin

Vacuum belt with powerful suction under the camera for holding the carton firmly.

Camera1 : 2K colour camera for inspecting of printing defects.

Camera2 : 4K black & white to inspect surface defects.(like foli stamping, coating and lamination defects).

Camera 3 – Bottom, 2K monochrome for checking presence of dead insects.

High speed fail proof pneumatic ejection system with air jets for segregating good and defective cartons separately.

Full tracking system is incorporated to track each and every carton to ensure the same carton is going to reject/accept delivery stacker

Delivery stacker with servo control for stream stacking.

Curved conveyor for collecting rejected cartons without the chance to mix-up.

Air jets are provided for cleaning camera lens periodically to improve the image quality

Ergonomically placed operator control with touch panel and PLC for easy setup of various parameters Monitor for viewing good and reject cartons on the run.

Machine with rugged frame design

All operator touch areas, are with corrosion free stainless steel and hard chrome plated parts.

Online UPS system with auto power shutdown for computer, light and camera to improve the reliability of the parts

Camera unit is independent of the machine and hence completely vibration free for excellent image quality

Individual LED lighting for each camera with angular mirror for precise image of metpet cartons

High precision industrial encoder is used with stable mounting for getting excellent quality and accuracy of scanned images

Modular design of guards for easy accessibility

Single wide bottom belt is provided for faster make ready Acoustic enclosures are provided in guards for reduced noise level

Bottom camera is provided with dust exhaust system for preventing false rejection due to dust floating in the air

Powerful main drive with timer belt for all drive shafts for eliminating slip and enhancing efficiency of the machine

Machine is completely designed to run on sealed bearings and hence it is maintenance free

Cooling system for computer and also for camera area

Brush and high speed nozzles for eliminating dust